What are common container air conditioning errors and how to fix them? What should you keep in mind when using refrigerated containers? Join Hung Thinh Container to answer all these issues in the article shared below!

Container air conditioner errors, how to fix them and notes when using

Common container air conditioning errors and how to fix them

During use, it is inevitable that container air conditioners will be faulty or damaged. Below are 3 common errors that can be fixed yourself that Hung Thinh Container has compiled. For more complex container air conditioning errors, you need to refer to the information in the error code table or contact repair units to ensure effectiveness and safety.

The temperature inside the container does not decrease or increase on its own

Unstable temperature is one of the common container air conditioning errors. If this error is detected during operation, it can be fixed by lifting the M.D switch for about 2 seconds and then dropping it (for DAIKIN machines, press the “MANUAL DEFROST” button and then press “ENTER”).

The condenser is not working properly

The condenser (condenser unit) is a part that easily gets dusty and is difficult to clean. Therefore, placing the device in a place that is often affected by rain and dust without a roof will easily get dirty. If this situation lasts for a long time, the dust layer will accumulate more and more, becoming glue on the tube surface, causing the heat transfer efficiency of the device to decrease.

To overcome this situation, it is necessary to regularly clean the condenser surface with a spray nozzle.

Poor condenser performance is one of the common container air conditioning errors

The air conditioner has weak temperature

This is one of the most common container air conditioning errors today, occurring due to many different reasons. Specifically:

- Before being put into the container, the goods have not been cooled or cooled to the set temperature, leading to low cooling efficiency.

- Using inappropriate packaging for goods.

- The arrangement of goods in the container is not reasonable, hindering air flow and affecting the effectiveness of maintaining temperature.

- Each type of goods when refrigerated will have different required temperatures. Inappropriate temperature setting is also one of the causes of reduced container cooling efficiency.

To fix these container air conditioner errors, operators need to follow the usage principles shared in the next section.

Operating principles to avoid common container air conditioning errors

General principles when using to avoid container air conditioner errors

- Refrigerated containers are designed with the main purpose of maintaining cargo temperature. Therefore, to ensure the best performance of the equipment, the goods need to be cooled to the set temperature before being packed into the container.

- For goods that have been refrigerated with a negative temperature setting, it is necessary to turn off the machine during the packing process, and only start the machine when the door is closed.

- Packaging and arranging goods need to be done carefully and thoroughly, choosing the right type of packaging for each type of goods.

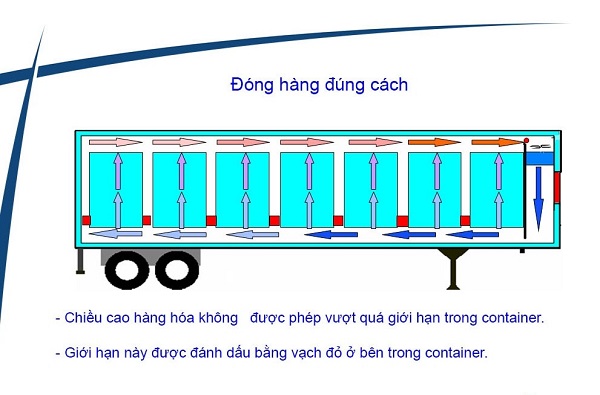

- Arrange goods neatly, properly, and appropriately refrigerated container size, Do not exceed the red line in the container to avoid obstructing the circulation of airflow, affecting the effectiveness of maintaining temperature.

The image illustrates how to properly pack goods to avoid container air conditioning errors

- Always close the container control panel, avoid exposing the device to water.

- Do not damage or disassemble the refrigeration equipment.

- During the packing process, do not run the air conditioner.

- Run the air conditioner immediately after packing and bring the container back to the yard as soon as possible.

Before starting

Before starting and operating the container’s air conditioner, it is necessary to check whether the socket and plug are working well, dry and clean, and whether the power source is of good quality.

In case the 3-phase electricity is 220V, the maximum must be 230V and the minimum must be 190V. On the other hand, if the 3-phase power is 280V/440V, the maximum must be 440V and the minimum is 280V before inserting the plug into the power outlet. The power plug and type of electricity used must correspond to each other. Do not remove the power plug to connect directly to the power grid.

In addition, to ensure operational efficiency during operations, it is necessary to properly conduct the container inspection shared below.

- Step 1: Press and hold the “PRE TRIP” key on the keyboard until the Auto 1, Auto 2, Auto 3 modes appear.

- Step 2: Select the test mode by pressing the up and down joystick, then press “ENTER” to start the test.

- Step 3: Regularly check the display panel. If you see the ALARM light on, you need to press the “ALARM LIST” key to see what error the container is experiencing and notify the technician to fix it promptly.

Keyboard operation to check containers

During operation

For DAIKIN brand air-conditioned containers, just press the start/stop button to complete.

For THERMOKING air-conditioned containers, when operating, move the switch to the UNIT ON position to start and UNIT OFF to stop (the start switch is usually designed on the side of the control panel).

For containers using CARRIER brand air conditioners, when operating, you need to put the ST switch to position I if you want to run the machine and position O if you want to stop the machine.

Things to note when using to avoid container air conditioner errors

To avoid encountering unwanted container air conditioner errors, during use, businesses need to pay attention to the following issues:

- For goods that have not been cooled or cooled to a positive (+) temperature, the machine should not be run when packing, because this will significantly reduce the cooling efficiency. Only run the machine in cases where it is really necessary.

- For goods that have been cooled to negative (-) temperatures, the machine must be turned off when packing. Only when the door is closed can you run the machine.

- Do not pack goods that touch the container door or exceed the prescribed red line. Do not let goods fall into the air circulation groove on the floor to ensure the best air circulation.

- Run cold immediately after packing.

- For cooled or refrigerated goods, packing in winter needs to be divided into 2 times and in summer it should be divided into 3 times, with a time gap between each time of at least 6 hours.

- During the cold running process, regular monitoring and inspection is required. If the temperature inside the container has reached below 10°C, it means the machine is operating normally. On the contrary, if the temperature does not decrease or tends to increase, you need to start the snow removal mode by lifting the M.D switch for about 2 seconds and then dropping it (for DAIKIN machines, press the “MANUAL DEFROST” button and then press “ENTER”). In case other problems occur, you should notify the company for instructions on appropriate handling.

The unit repairs container air conditioning errors professionally, ensuring prestige

With more than 14 years of experience operating in the field of repair, rental, and sale of refrigerated containers, we own a team of technicians who are skilled engineers specializing in industrial welding, industrial electricity, and refrigeration. They are all experienced, professional, and trusted and chosen by many customers. Hung Thinh Container will definitely not disappoint businesses!

Reputable and professional unit for repairing container air conditioning errors

Above are the shares shared by Hung Thinh Container container air conditioning errors Common problems, solutions and notes when using. Hopefully this will be a useful reference for businesses. Contact Hung Thinh Container for advice on how to inspect refrigerated containers as well as related issues to make the storage and transportation of your business’s goods smoother and more effective.